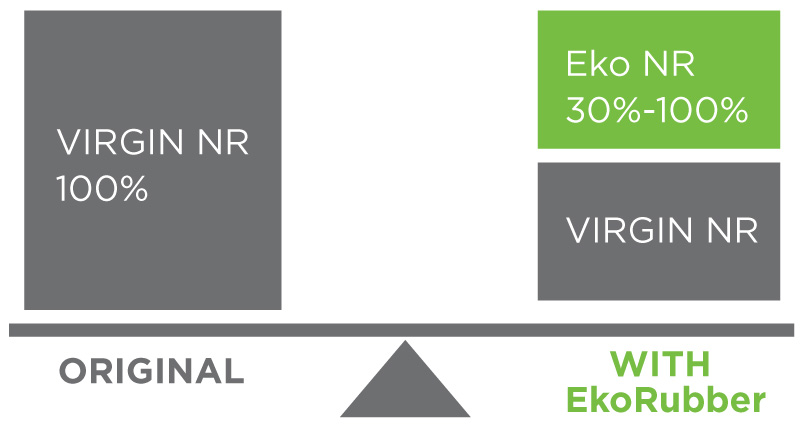

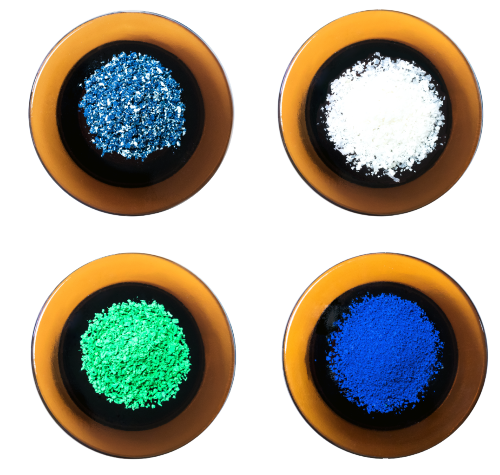

To meet your eco business objectives, we customize the chemical formula of each innovative application and exclusively Research and Development (R&D) in our laboratory a step by step process to find the best solutions for your product requirements. EKO Rubber, the reprocessed rubber polymer of uncontaminated non-tyre rubber scrap, can be a substitute for high cost material and have for more efficient production costs without compromising quality.

REuse

Clean Rubber Scrap

Where do we get

clean rubber scrap?

We gather expired and rejected rubber products which haven’t been used.

REduce

Environmental Footprint

How can you help?

Clean rubber scrap is reprocessed by Advanced Hybrid Devulcanization Method. You can use EKO Rubber to mix with your main raw materials

REstart

A Product’s Second Life

It’s also an opportunity.

For any rubber applications to become eco-friendly products but still maintain thier quality.

We work closely with various Rubber Research and Development Institutes to create the best alternate rubber solutions.