At BGS International Co., Ltd. (THAILAND), we offer Re-Waste Rubber Solution to turn

“Rubber Waste” to “Renewable Rubber Material”.

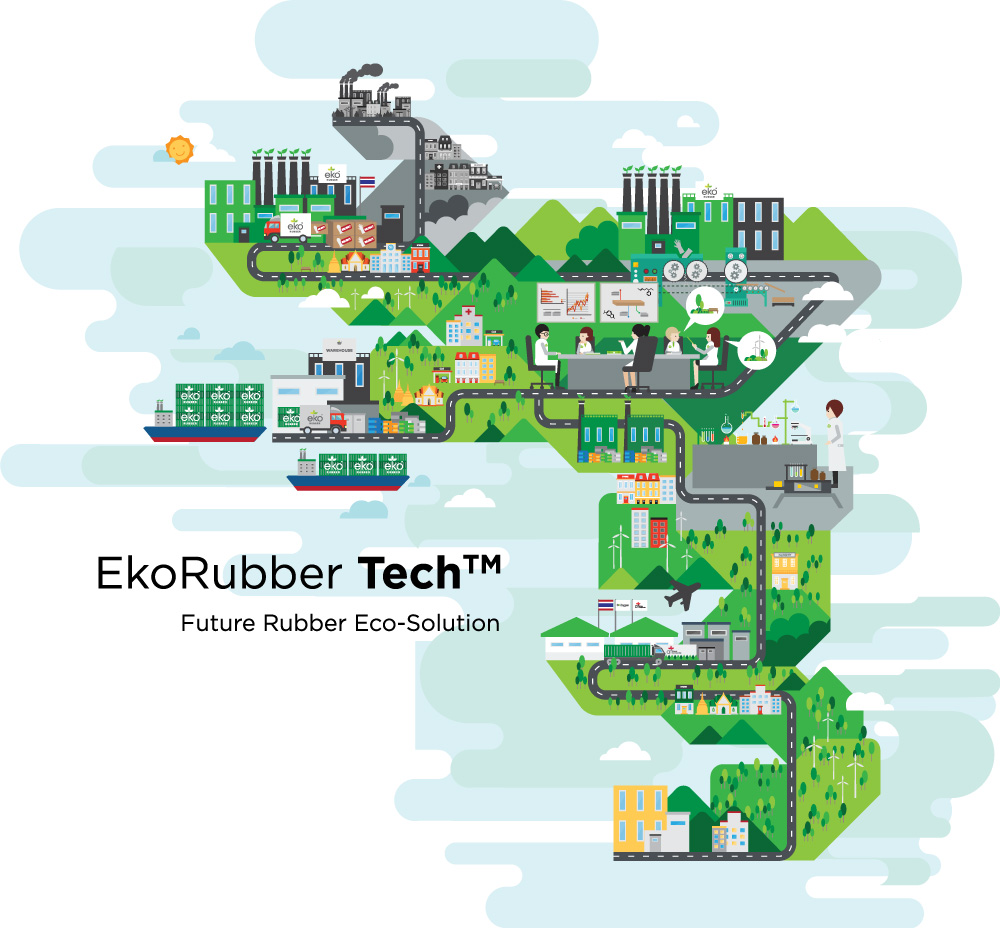

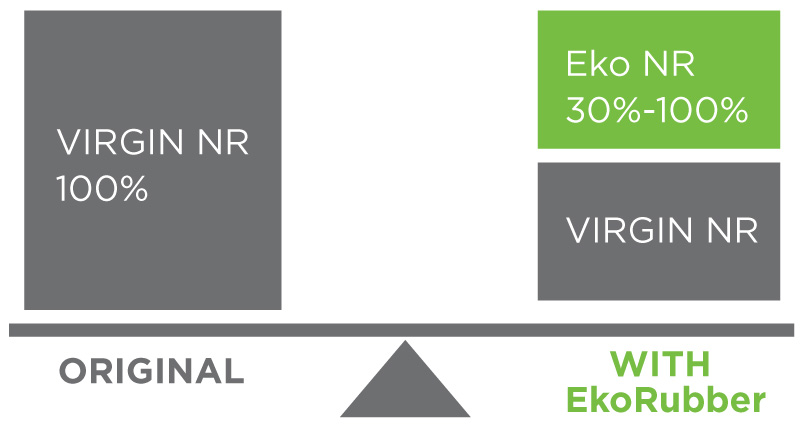

BGS is part of AF Group Company for over 45 years of experience in chemical engineering and polymer. With our advanced eco-friendly innovation, EkoRubber Tech™ gives a second life to pre-consumption rubber waste which we call Eko Rubber or Renewable Rubber Material. And these Eko Rubber™ is then used as one of key raw materials before becoming “Green Products” which can help companies to potentially launch their new “High Value Brand product and/or engaging new market” focus in Social and Environmental Responsibilities.

The EkoRubber Tech™ System is designed to have no impact to the environment (no air and water pollution). You can apply for Carbon Footprint and get Carbon Credit for using Eko Rubber. With EkoRubber Tech™ , you can recycle many rubber types in 20-25 Kg bale form.

1. LX-C3 Series

From pre-consumption latex waste

2. LX-G1 Series

From pre-consumption latex waste

3. NR-NM Series

From pre-consumption rubber product waste

lients will hire us to re-generate their rubber waste and use back in either their current products or new product lines. We will help provide solution and working closely with our internal R&D team.

The EkoRubber Tech™ Turnkey System is our “one-stop” complete services included:

– Hardware customization to make sure it fits with the site location

– Consultation for the Installation process to staff operation training

– Keeping inform any parts update to any future minor upgrade, we take care of it all.

This solution is fit for any customers who need recycling and would like to reused their

own rubber wastes internally.

Our R&D commits to find what maximum performance and properties each customer’s “rubber waste” can give, then we are able to suggest right formulation. Later we design and customize the right machine specifications for the right “rubber waste” to fit customer’s space and need.

We can deliver the “customized solution” in order to minimize risks, maximize waste output, ensure long lasting operation, utilizing space usages, with minimum amount of maintenance.